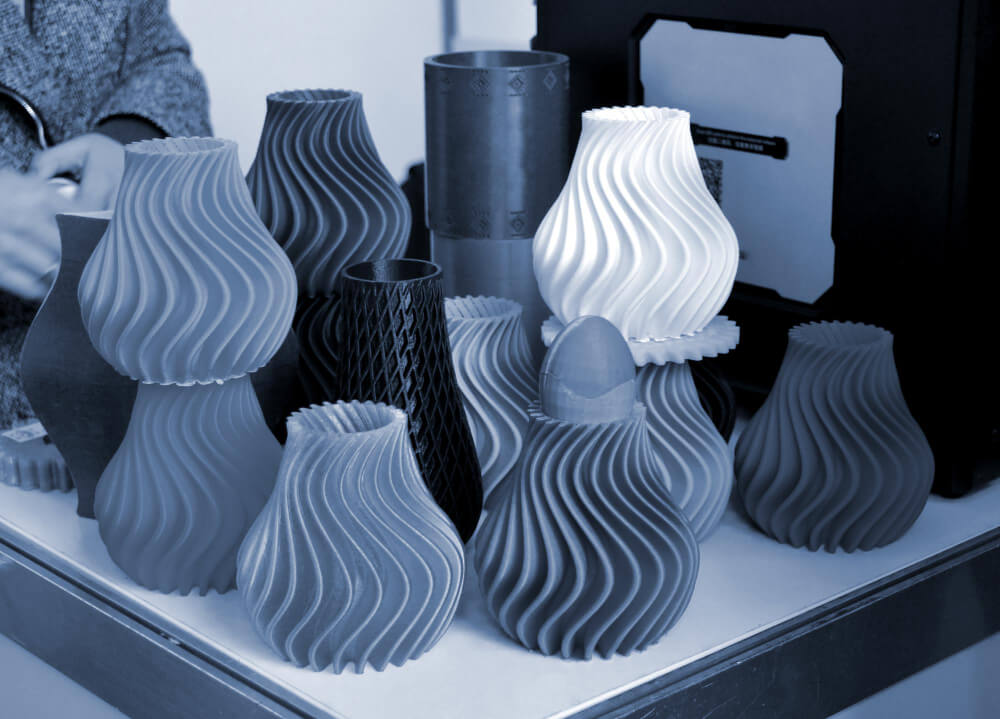

3D printed molding shapes have emerged as a revolutionary solution in various industries, offering unprecedented flexibility and efficiency in the production of molds for casting and manufacturing processes.

Traditionally, creating molds for specific shapes and designs involved time-consuming and costly processes such as machining or manual fabrication. However, with the advent of 3D printing, the entire mold-making process has been streamlined and accelerated.

One of the significant advantages of 3D printed molding shapes is their rapid production time. With traditional methods, creating molds could take days or even weeks. In contrast, 3D printing significantly reduces lead times, allowing for faster iteration and prototyping. This agility is particularly valuable in industries that require quick turnaround times, such as product design, automotive, aerospace, and consumer goods.

Moreover, 3D printed molds offer cost savings compared to traditional molds. The elimination of complex machining processes and the ability to produce molds on-demand significantly reduce upfront costs and tooling expenses. This makes it economically viable to produce molds for smaller production runs or unique designs that wouldn’t be cost-effective with traditional methods.